Detailed Species Information

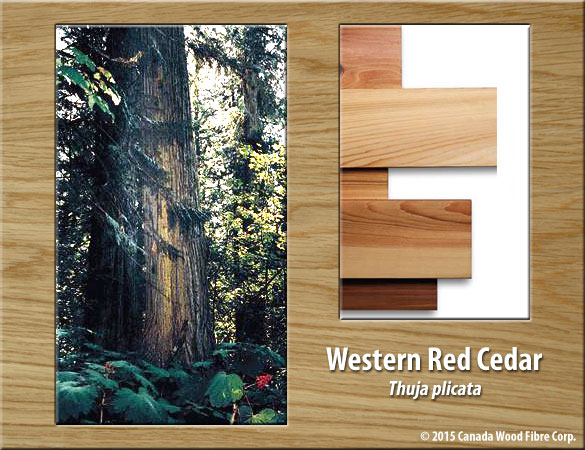

Western Red Cedar (Thuja plicata)

Western red cedar grows at low-to-mid elevations along the Coast and in the wet belt of the Interior, where the climate is cool, mild and moist. It is a large tree, up to 60 metres tall when mature and 2.5 metres in diameter. It is rarely found in pure stands and is often mixed with Douglas-fir, Sitka spruce, black cottonwood and red alder. Western red cedar makes up approximately 8% of British Columbia’s total growing stock, and is one of the most commercially valuable species.

Common Uses

Due to the unique properties of western red cedar, have been developed for a variety of different applications. The main attribute of western red cedar is its excellent durability and dimensional stability, leading to uses such as roof shingles, exterior siding, exterior cladding, decking, weather boarding, greenhouses, portable buildings, bee-hives, poles, posts, fences, ship and boat building, as well as boxes and crates. Red cedar is a popular wood for outdoor furniture and playground equipment.

Western red cedar is an attractive wood that is also used in interior applications. This wood is popular for sashes, doors and windows, ceiling and wall panelling, as well as for millwork. Due to its dimensional stability it is perfectly suited to uses such as sauna panelling, mouldings and window blinds. Red cedar is also a good choice for musical instruments due to its superb acoustic resonance properties.

Physical Properties

| Density (kg/m3) | Green | 330 |

| Air Dry | 339 | |

| Specific Gravity (12% M.C.) | Standard | 0.33 |

| Hardness (N) | Side | 1470 |

| End | 3000 | |

| MOE (Mpa) | Green | 7240 |

| Air Dry | 8270 | |

| MOR (Mpa) | Green | 36.5 |

| Air Dry | 53.8 | |

| Compression Parallel (Mpa) | Air Dry | 33.9 |

| compression Perpendicular (Mpa) | Air Dry | 3.43 |

| Shear (Mpa) | Air Dry | 5.58 |

| Cleavage (N/mm Width) | Air Dry | 25.4 |

| Shrinkage OD=oven dry air=air dry 12% |

Radial (OD) | 2.1% |

| Tangential (OD) | 4.5% | |

| Volumetric (OD) | 7.8% | |

| Volumetric (air) | 4.8% | |

| Tang / Rad ratio | 2.1 |

Working Properties

Western red cedar is a fairly lightweight wood, which is moderately soft and low in strength. It is known for its excellent working properties, and its ability to take a smooth, satiny finish with sharp tools. It is relatively easy to work, with good machining qualities. It planes and shapes well and can be sanded to a smooth finish. The wood glues easily, has moderate nail and screw holding ability, and takes a good finish.

| Process | Performance | Comments |

| Machining | ||

| Planing | Moderate to good | Recommended planer settings: 20° hook and 20 kmpi (knife marks per inch). Wood is subject to compression during planing. Must use sharp cutting tools. Wood is somewhat brittle and splintering is common. |

| Turning | Medium to low surface quality |

Common defects: torn out grain. |

| Sawing | Easy to work with tools | Easy to saw because of its low density. Corrosive properties can be damaging to cutting blades. |

| Boring | Good to medium | Good boring quality with brad point bits and moderate quality with single twist bits. |

| Mortising | Moderate | Better mortising quality is found with a hollow chisel mortise. |

| Shaping | Good shaping quaility | Splintering on the end-grain may be an issue.

Recommended: The use of a counter piece for end-grain shaping. |

| Veneering | N/A | |

| Sanding | Excellent | |

| Fastening | ||

| Screwing | Low to moderate | Average screw retention: 308 lb. |

| Lateral Nail Holding | N/A | |

| Nail Retention | Low to moderate | Due to the acidic properties of its extractives this wood tends to accelerate the corrosion of metals, particularly when in contact with unprotected ferrous metal. Hot-dipped galvanized nails are recommended. It is essential that stainless steel, brass, aluminium, copper or metals with a protective coating be used when applying fittings, fixtures or fasteners. |

| Gluing | Easy | Bonds very easily with adhesives of a wide range of properties and under a wide range of bonding conditions. |

| Finishing | ||

| Staining | Easy | Very smooth texture achieved, but sometimes difficult to hide natural texture of wood. Very soft wood that loses some grain design as stain becomes darker. Some wild grain was present in Interior red cedar. |

| Painting | Moderate to good paint holding ability | |

| Lacquering | Good | Clear coats with little difficulty. A high build clear coat works best for the coastal wood while it was recommended for Interior red cedar to use a clear finish, nitrocellulose/alkyd sealer and finish system.

Performed well in the tape test (i.e. small flakes of the coating were detached along edges and at intersections of cuts) and in the pull-off test |

| Waxing | Good | Good results are obtained when using light-, medium- or dark-coloured waxes (e.g. Mellow Pine, Chestnut or Jacobean). |

| Drying | ||

| Ease of Drying | Moderately easy to difficult | The drying of thin boards is generally easy with little degrade occurring. As red cedar tends to hold its moisture at the centre, care is required when drying thicker stock as internal honey-combing and collapse are common defects. Longer drying times are required. |

| Durability | ||

| Natural Decay Resistance | Durable | Appropriate for outdoor usage. |

| Treatability | Impermeable to extremely impermeable |

Can be improved by incising. |

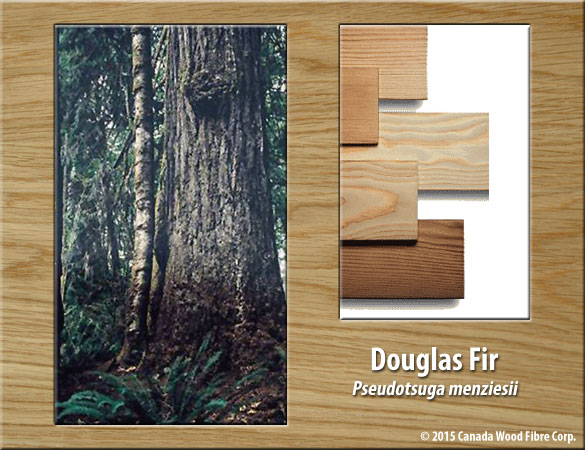

Douglas Fir (Pseudotsuga menziesii)

Douglas fir is one of the best known wood species in the world. Douglas-fir is a large tree reaching heights of 85 metres.

Common Uses

Douglas-fir is primarily used for building and construction purposes due to its strength advantages and availability of large dimensions from old-growth trees. It is one of the finest timbers for heavy structural purposes, including laminated arches and roof trusses. Structurally, it is used in the form of lumber, timbers, pilings and plywood.

Douglas-fir is seen as a first class wood for the manufacturing of sashes, doors and windows. The wood is also used to produce a wide variety of products including general millwork, flooring, furniture, cabinets, veneer, vats, ship and boat construction, transmission poles, and marine pilings.

Douglas-fir lumber is dried according to end-use and customer specifications. Kiln drying inhibits natural staining of the wood, improves its strength and stiffness, enhances its appearance, and increases its resistance to decay and attack by insects.

Physical Properties

| Density (kg/m3) | Green | 450 |

| Air Dry | 487 | |

| Specific Gravity (12% M.C.) | Standard | 0.45 |

| Hardness (N) | Side | 2990 |

| End | 4020 | |

| MOE (Mpa) | Green | 11100 |

| Air Dry | 13500 | |

| MOR (Mpa) | Green | 52.0 |

| Air Dry | 88.6 | |

| Compression Parallel (Mpa) | Air Dry | 50.1 |

| compression Perpendicular (Mpa) | Air Dry | 6.01 |

| Shear (Mpa) | Air Dry | 9.53 |

| Cleavage (N/mm Width) | Air Dry | 38.9 |

| Shrinkage OD=oven dry air=air dry 12% |

Radial (OD) | 4.8% |

| Tangential (OD) | 7.4% | |

| Volumetric (OD) | 11.9% | |

| Volumetric (air) | 7.0% | |

| Tang / Rad ratio | 1.5 |

Working Properties

Douglas-fir has excellent strength properties and is well known for its workability. The wood dries rapidly with small dimensional movement and little tendency to check. It is relatively easy to work, with good machining qualities. It turns, planes and shapes well and can be sanded to a smooth finish. The wood glues moderately easily, has moderate nail and good screw holding ability, and takes a good finish.

| Process | Performance | Comments |

| Machining | ||

| Planing | Good planing quality | Good surface quality. Typical defects are raised grain and fuzzy grain. |

| Turning | High surface quality | Very good surface quality. |

| Sawing | Easy to work with tools | Easy to work with both hand and power tools. Moderate to severe blunting effect. Resin build up on cutters may cause problems. |

| Boring | Good | Very good boring quality. |

| Mortising | Excellent | Excellent mortising quality with both chain mortise and hollow chisel mortise. |

| Shaping | Excellent shaping quality | |

| Veneering | Excellent | Important plywood species. |

| Sanding | Good | Very good sanding properties. |

| Fastening | ||

| Screwing | Good | Very good holding. Excellent resistance to splitting. A verage screw retention: 494 lb. |

| Lateral Nail Holding | Good | Good holding. Excellent resistance to splitting. |

| Nail Retention | Good | |

| Gluing | Glues to moderate | Bonds well with a fairly wide range of adhesives under a moderately wide range of bonding conditions. |

| Finishing | ||

| Staining | Easy | Old-growth: Smooth finish. Grain becomes wild and pronounced with dark stain. A clear coating works the best. Second-growth: Stainability is average for light colours, poor for dark ones. Good results with light stain or clear finish followed by nitrocellulose alkyd clear sealer and finish. Rotary cut veneers are reported to display such strong natural color that staining is sometimes unnecessary. |

| Painting | Average to good paint holding ability | Satisfactory to good results. |

| Lacquering | Excellent results | |

| Waxing | Good | Very good results are obtained when using light- to medium-coloured waxes, such as Mellow Pine and Chestnut. |

| Drying | ||

| Ease of Drying | Easy to moderately easy | A relatively easy wood to dry with little trouble occurring from checking, warping and splitting. Lower grades require more care. |

| Durability | ||

| Natural Decay Resistance | Moderately durable | Should not be used in applications with prolonged ground contact without treatment. |

| Treatability | Impermeable to extremely impermeable |

Engelmann Spruce (Picea engelmannii)

Engelmann spruce occurs at high elevations and interbreeds with white spruce in areas where their ranges overlap, and they are referred to as Interior spruce.

Common Uses

Engelmann pruce wood is highly valued for lumber, plywood and pulp production. As dimension lumber, Engelmann spruce is extremely versatile because of its high strength-to-weight ratio. It is used in building construction (framing, sheathing, roofing, sub-flooring), general millwork, interior finishing, boxes and packing cases. Its dimensional stability and superior gluing properties make it popular in the prefabrication industry. Engelmann spruce is used in the manufacture of modular houses, trusses, and other structural components that specify kiln-dried SPF wood. As a premier pulpwood, the species is used in the manufacture of newsprint and bleached Kraft pulps. It is also used in the manufacture of medium density fiberboard (MDF), paperboard and felt, and it is a major species used in Canadian softwood plywood. Other uses of white spruce include: sounding boards in musical instruments from select materials, food containers (because it is almost colourless and odourless when dried), paddles and oars, cooperage, organ pipes, shelving, and ladder rails.

Physical Properties

| Density (kg/m3) | Green | 306 |

| Air Dry | 390 | |

| Specific Gravity (12% M.C.) | Standard | 0.36 |

| Hardness (N) | Side | 1880 |

| End | 2470 | |

| MOE (Mpa) | Green | 7930 |

| Air Dry | 9930 | |

| MOR (Mpa) | Green | 35.2 |

| Air Dry | 62.7 | |

| Compression Parallel (Mpa) | Air Dry | 36.9 |

| compression Perpendicular (Mpa) | Air Dry | 3.45 |

| Shear (Mpa) | Air Dry | 6.79 |

| Cleavage (N/mm Width) | Air Dry | 38.7 |

| Shrinkage OD=oven dry air=air dry 12% |

Radial (OD) | 3.2% |

| Tangential (OD) | 6.9% | |

| Volumetric (OD) | 11.3% | |

| Volumetric (air) | 6.8% | |

| Tang / Rad ratio | 1.6 |

Working Properties

Spruce has a high strength-to-weight ratio and is well known for its working properties. The wood dries rapidly with small dimensional movement and little tendency to check. It is relatively easy to work, with good machining qualities. It turns, planes and shapes well and can be sanded to a smooth finish. The wood glues moderately easily, has moderate nail and screw holding ability, and takes a good finish.

| Process | Performance | Comments |

| Machining | ||

| Planing | Easy. Good quality | Good planing quality. Typical defect is raised grain. Recommended planer settings: 12° or 20° hook angle and 20 kmpi (knife marks per inch). |

| Turning | Satisfactory | Satisfactory surface quality when using rotary-knife lathe and poor when using a single point lathe. Common defect: torn out grain. |

| Sawing | Good | Easily worked with hand and power tools. Slight to moderate blunting effect. While knots can sometimes be a problem, the wood can be sawn cleanly, with sharp cutting edges |

| Boring | Medium quality | Medium boring quality using brad point bits. |

| Mortising | Good | Very good mortising quality using both a hollow chisel and a chain mortise. |

| Shaping | Good | Good shaping quality. Common shaping defects in the order of frequency: splintering at the corner, rough end-grain, fuzzy grain, raised grain, and torn grain. Recommended: the use of a counter piece for end-grain shaping. |

| Veneering | N/A | |

| Sanding | Very good | |

| Fastening | ||

| Screwing | Satisfactory to good holding | Very good resistance to splitting. Average screw retention: 347 lb. |

| Nailing Retention | Satisfactory to good holding | Very good resistance to splitting. |

| Lateral Nail Holding | Moderate | |

| Gluing | Moderately easy to glue | |

| Finishing | ||

| Staining | Good | Good staining properties. A smooth finish is achieved. A natural finish (clear coat) or a light stain looks the best. |

| Painting | Satisfactory | |

| Lacquering | Good | Good results. Performs very well in the tape test (i.e. small flakes of the coating were detached at intersections of cuts, less than 5% of the area affected) and well in the pull-off test (i.e. average strength of 31 kg/cm2). |

| Waxing | Good | Easy and with good results. Best when using light-coloured waxes (e.g. Mellow Pine). |

| Drying | ||

| Ease of Drying | Easy to moderately easy | Spruce dries faster than pine and is not adversely affected by severe high-temperature schedules. |

| Durability | ||

| Natural Decay Resistance | Non-resistant to heartwood decay | |

| Treatability | Very resistant to impregnation with preservatives |

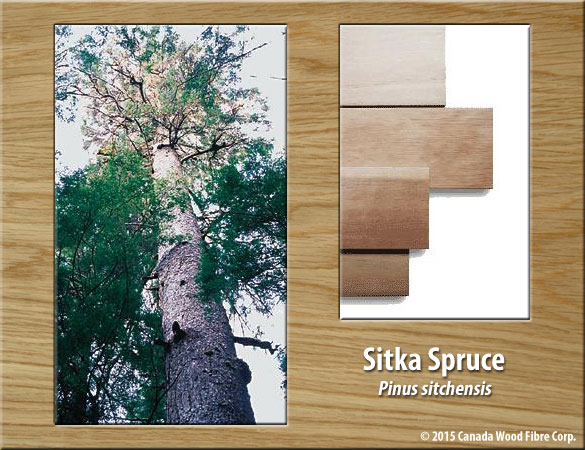

Sitka Spruce (Pinus sitchensis)

This tree is the largest of the spruces and grows up to 70 metres tall and 2 metres in diameter.

Common Uses

Sitka spruce is used in a variety of structural products. High grades of Sitka spruce are popular for specialty marine applications such as masts, spars and deck beams, and for ladder stock and industrial equipment where a high strength-to-weight ratio is desired. During the First World War this species assumed great importance for airplane construction.

Clear grades are used in fine interior finishing such as sliding screens, mouldings, joinery and trim. It is particularly popular when an even-coloured natural wood finish is desired. The top grade clear wood is used for piano and guitar sound-boards as it has excellent resonating properties.

Sitka spruce lumber is dried according to end-use and customer specifications. Kiln drying inhibits natural staining of the wood, improves its strength and stiffness, enhances its appearance, and increases its resistance to decay and attack by insects.

Physical Properties

| Density (kg/m3) | Green | 347 |

| Air Dry | 387 | |

| Specific Gravity (12% M.C.) | Standard | 0.35 |

| Hardness (N) | Side | 2200 |

| End | 3090 | |

| MOE (Mpa) | Green | 9450 |

| Air Dry | 11200 | |

| MOR (Mpa) | Green | 37.4 |

| Air Dry | 69.8 | |

| Compression Parallel (Mpa) | Air Dry | 37.8 |

| compression Perpendicular (Mpa) | Air Dry | 4.10 |

| Shear (Mpa) | Air Dry | 6.78 |

| Cleavage (N/mm Width) | Air Dry | 38.0 |

| Shrinkage OD=oven dry air=air dry 12% |

Radial (OD) | 4.6% |

| Tangential (OD) | 7.8% | |

| Volumetric (OD) | 11.7% | |

| Volumetric (air) | 6.0% | |

| Tang / Rad ratio | 1.7 |

Working Properties

Sitka spruce has a high strength-to-weight ratio and is well known for its working properties. The wood dries rapidly with small dimensional movement and little tendency to check. It is relatively easy to work, with good machining qualities. It planes and shapes well and can be sanded to a smooth finish. The wood glues easily, has moderate nail and screw holding ability, and takes a good finish.

| Process | Performance | Comments |

| Machining | ||

| Planing | Excellent planing quality | Recommended planer settings: 12ohook angle and20 kmpi (knife marks per inch). Takes a smooth silky finish provided sharp tools are used. |

| Turning | Medium to low surface quality | Common defects: torn out grain. |

| Sawing | Easy to work with tools | Easy to work provided cutting edges are kept sharp and the wood is free of knots. |

| Boring | Medium | Medium to good boring quality with brad point bits and lower quality with single twist bits. |

| Mortising | Good | Good mortising quality when using both chain and hollow chisel mortises. |

| Shaping | Good shaping quality | Recommend the use of a counter piece for end-grain shaping. |

| Veneering | Good | |

| Sanding | Good | Excellent sanding quality. |

| Fastening | ||

| Screwing | Moderate | Average screw retention: 402 lb. |

| Lateail Holding | N/A | |

| Nail Retention | Good | |

| Gluing | Easy | Bonds very easily with adhesives of a wide range of properties and under a wide range of bonding conditions. |

| Finishing | ||

| Staining | Easy to moderate | Smooth finish achieved. Light stains work well but dark stains magnify the uneven colours produced by different textures in wood. A wash coat would even out the colour. |

| Painting | Average to good paint holding ability | |

| Lacquering | Good | |

| Waxing | Good | Best results are obtained when using light-coloured waxes (e.g. Mellow Pine). |

| Drying | ||

| Ease of Drying | Easy to moderately easy | Dries rapidly and quite well, but care is required to reduce warping, splitting and loosening of knots. |

| Durability | ||

| Natural Decay Resistance | Slightly durable | Not appropriate for prolonged outdoor exposure. |

| Treatability | Impermeable | Can be improved by incising. |

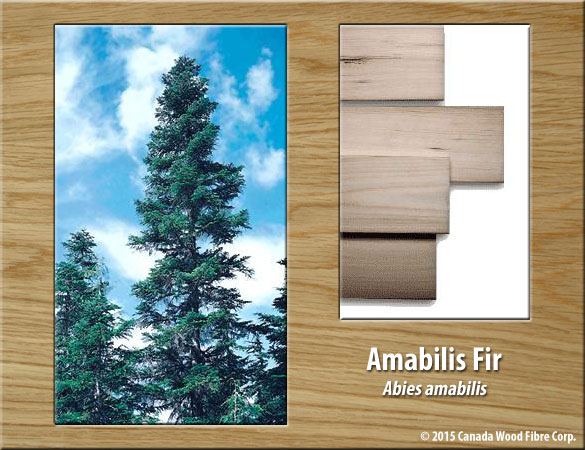

Amabilis Fir (Abies amabilis)

Amabilis fir is a tall straight tree that can reach 50 meters in height and 1 meter in diameter, and is a shade-tolerant species.

Common Uses

Amabilis fir is used in structural products, due to its strength properties. Widely used in a range of residential and commercial construction in applications such as framing, sheathing, sub-flooring, concrete forms, decking, planking, beams, posts, and prefabricated buildings. Low-grade wood is used in both pulp and paper products, as well as for boxes and crates.

High-grade Amabilis fir is used in interior applications as it is an attractive species with good working properties. Because of its light weight and colour and its clean appearance, the wood is used for doors and windows, furniture parts, mouldings, sauna panelling, and food containers.

Research has shown Amabilis fir to be among the most treatable wood species in Canada. This provides an opportunity to add value to the species through pressure treating.

Amabilis fir lumber is dried according to end-use and customer specifications. Kiln drying inhibits natural staining of the wood, improves its strength and stiffness, enhances its appearance, and increases its resistance to decay and attack by insects.

Working Properties

Amabilis fir has a high strength-to-weight ratio and is well known for its working properties. The wood dries moderately quickly with small dimensional movement and little tendency to check. It is relatively easy to work, with good machining qualities. It planes and shapes well and can be sanded to a smooth finish. The wood glues easily, has a moderate nail and screw holding ability, and takes a good finish.

| Process | Performance | Comments |

| Machining | ||

| Planing | Fair to good results | Recommended planer settings 20ohook angle and 20 kmpi (knife marks per inch). Typical defects: Fuzzy grain, raised grain, and torn grain. Sharp tools are needed in order to overcome the tendency for grain tearing. |

| Turning | Moderate to poor surface quality | Much better surface quality when rotary-knife lathe is used. |

| Sawing | Variable | Slight to moderate blunting effect |

| Boring | Medium | Medium boring quality with brad point bits and poor quality with single twist bits. |

| Mortising | Moderate to good | Good mortising quality when using a hollow chisel mortise |

| Shaping | Good shaping quality | Recommended: The use of a counter piece for end-grain shaping. |

| Veneering | N/A | |

| Sanding | Good | Sands smoothly |

| Fastening | ||

| Screwing | Moderate | Average screw retention: 366 lb. |

| Nail Retention | Moderate to good | Good holding. |

| Lateral Nail Holding | N/A | |

| Gluing | Glues easily | Bonds very easily with adhesives of a wide range of properties and under a wide range of bonding conditions. |

| Finishing | ||

| Staining | Average to good | Wood is soft and produces a grainy appearance. Natural and light stains look the best. Dark stains appear blotchy. |

| Painting | Average to good paint holding ability | |

| Lacquering | Good | Multiple coats of clear or a clear coat with a high build is recommended. |

| Waxing | Good | Good results. Best results are obtained when using light-to-mid coloured waxes (e.g. Mellow Pine, Chestnut). |

| Drying | ||

| Ease of Drying | Moderately easy to mederatly difficult | There is a wide variation in the moisture content of green western hemlock. Best results are obtained when sorting by moisture content of this wood, longer kiln drying times are required. When dried at high temperatures sapwood can turn a brownish colour. |

| Durability | ||

| Natural Decay Resistance | Non-durable to slightly durable | Not appropriate for prolonged outdoor exposure. |

| Treatability | Moderate |

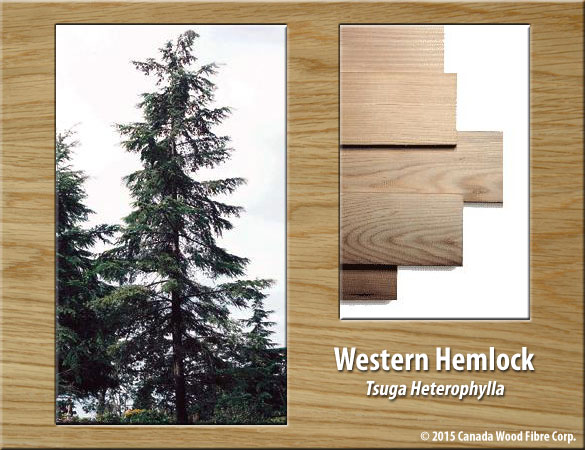

Western Hemlock (Tsuga heterophylla)

On average it typically grows 30 to 50 metres tall and 1 to 1.5 metres in diameter.

Common Uses

Western hemlock is used for general construction, roof decking and plywood. It is used for laminating stock and the production of glue laminated and solid beams. Hemlock can also be used for pulp and newsprint.

Western hemlock is firmly established as an outstanding wood for mouldings and is also used for interior woodworking. Other uses include: doors, windows, interior finish, floors, suspended ceilings, ladders, and other purposes where a high-grade softwood is needed.

Western hemlock lumber is dried according to end-use and customer specifications. Kiln drying inhibits natural staining of the wood, improves its strength and stiffness, enhances its appearance, and increases its resistance to decay and attack by insects.

Physical Properties

| Density (kg/m3) | Green | 420 |

| Air Dry | 429 | |

| Specific Gravity (12% M.C.) | Standard | 0.42 |

| Hardness (N) | Side | 2740 |

| End | 4410 | |

| MOE (Mpa) | Green | 10200 |

| Air Dry | 12300 | |

| MOR (Mpa) | Green | 48.0 |

| Air Dry | 81.1 | |

| Compression Parallel (Mpa) | Air Dry | 46.7 |

| compression Perpendicular (Mpa) | Air Dry | 4.53 |

| Shear (Mpa) | Air Dry | 6.48 |

| Cleavage (N/mm Width) | Air Dry | 37.5 |

| Shrinkage OD=oven dry air=air dry 12% |

Radial (OD) | 5.4% |

| Tangential (OD) | 8.5% | |

| Volumetric (OD) | 13.0% | |

| Volumetric (air) | 8.1% | |

| Tang / Rad ratio | 1.6 |

Working Properties

Western hemlock has a relatively good strength-to-weight ratio and is known for its working properties. The wood requires special care when drying but yields a quality product. Western hemlock is known for its even density which provides for excellent machining properties. It turns, planes and shapes well and can be sanded to a smooth finish. The wood glues satisfactorily, has moderate nail and screw holding ability, and takes a good finish.

| Process | Performance | Comments |

| Machining | ||

| Planing | Fair to good results | Typical defects: Fuzzy grain, raised grain, and chip marks. |

| Turning | Good surface quality | Easy. Good results. |

| Sawing | Easy to difficult | Varies from difficult to easy. Slight to moderate blunting effect. |

| Boring | Good | Responds well to boring operations. |

| Mortising | Good | Easy. Finishes well. |

| Shaping | Moderate shaping quality | Easy, with moderate surface quality. |

| Veneering | Good | |

| Sanding | Good | Good sanding finish. |

| Fastening | ||

| Screwing | Moderate | Intermediate holding. Tendency to split. Good results if pre-drilled. Average screw retention: 470 lb. |

| Lateral Nail Holding | Good | Tendency to split. |

| Nail Retention | Good | |

| Gluing | Glues satisfactorily | |

| Finishing | ||

| Staining | Average to good | Old-growth: Smooth texture achieved. As stain gets darker, prominent wild grain is visible. A wash coat would even out the colour. Second-growth: Stainability is average for light colours, poor for dark. Best finish is with light stain or clear finish followed by nitrocellulose alkyd clear sealer and finish. |

| Painting | Average to good paint holding ability | Satisfactory paint holding ability. |

| Lacquering | Good | Old-growth: Natural finish (clear coat) looks best. Satisfactory results. Second-growth: Excellent results with clear coat. |

| Waxing | Good | Good results. Best results are obtained when using light coloured waxes (e.g. Mellow Pine). |

| Drying | ||

| Ease of Drying | Moderately easy to moderately difficult | There is a wide variation in the moisture content of green western hemlock. Best results are obtained when sorting by moisture content is done. Due to the high moisture content of this wood, longer kiln drying times are required. When dried at high temperatures sapwood can turn a brownish colour. |

| Durability | ||

| Natural Decay Resistance | Slightly durable | Not appropriate for prolonged outdoor exposure. |

| Treatability | Impermeable | Can be improved by incising. |

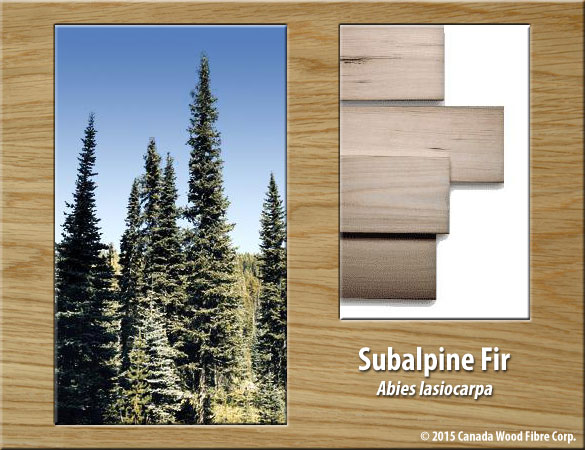

Subalpine Fir (Abies lasiocarpa)

It is a medium-sized tree, on average 20 to 35 metres in height and 30 cm in diameter.

Common Uses

Subalpine fir kiln dried lumber is used as a structural framing material in all types of residential, commercial, industrial and agricultural building applications. Kiln dried SPF lumber is also used extensively in the manufacture of prefabricated housing, trusses and other structural components.

This wood is also used for plywood veneers, planing-mill products, crates and boxes, sashes, doors, frames, food containers, pulpwood and general millwork. Subalpine fir is used with spruce and lodgepole pine for producing 100% bleached Kraft pulp and chemi-thermo-mechanical pulp (CTMP).

Subalpine fir lumber is dried according to end-use and customer specifications. Kiln drying inhibits natural staining of the wood, improves its strength and stiffness, enhances its appearance, and increases its resistance to decay and attack by insects.

Physical Properties

| Density (kg/m3) | Green | 331 |

| Air Dry | 351 | |

| Specific Gravity (12% M.C.) | Standard | 0.33 |

| Hardness (N) | Side | 1557 |

| End | n/a | |

| MOE (Mpa) | Green | 8690 |

| Air Dry | 10300 | |

| MOR (Mpa) | Green | 35.6 |

| Air Dry | 55.2 | |

| Compression Parallel (Mpa) | Air Dry | 35.4 |

| compression Perpendicular (Mpa) | Air Dry | 3.61 |

| Shear (Mpa) | Air Dry | 6.74 |

| Cleavage (N/mm Width) | Air Dry | n/a |

| Shrinkage OD=oven dry air=air dry 12% |

Radial (OD) | 2.6% |

| Tangential (OD) | 7.4% | |

| Volumetric (OD) | 9.4% | |

| Volumetric (air) | n/a | |

| Tang / Rad ratio | 2.8 |

Working Properties

| Process | Performance | Comments |

| Machining | ||

| Planing | Good planing quality | Recommended planer settings: 12ohook angle and20 kmpi (knife marks per inch). Due to the usually wide bands of soft earlywood there is a definite tendency for these to become compressed during planing, later lifting to give a ridged surface. |

| Turning | Medium to low surface quality | Common defects: torn out grain. |

| Sawing | Easy to work with tools | Due to the usually wide bands of soft earlywood there is a definite tendency for these to tear in sawing. |

| Boring | Medium | Medium boring quality with both brad and single twist bits. Due to the usually wide bands of soft earlywood there is a definite tendency for these to tear in boring operations. |

| Mortising | Good to moderate | Good mortising quality when using a hollow chisel mortise. Due to the usually wide bands of soft earlywood there is a definite tendency for these to tear in mortising. Common mortising defects: splintering on the out-going side of the mortise and crushed grain inside the mortise. |

| Shaping | Good shaping quality | Common shaping defects in the order of frequency: Splintering at the corner, rough end-grain, fuzzy grain, raised grain, and torn grain. Recommended: The use of a counter piece for end-grain shaping. |

| Veneering | N/A | |

| Sanding | Good | |

| Fastening | ||

| Screwing | Moderate | Average screw retention: 313 lb. |

| Nail Retention | Moderate | |

| Lateral Nail Holding | Moderate | About 40% reduction to Douglas-fir. |

| Gluing | Easy | Bonds very easily with adhesives of a wide range of properties and under a wide range of bonding conditions. |

| Finishing | ||

| Staining | Easy | Smooth finish with little texture. Dark stain produces prominent wild grain. Recommended: light-coloured stains with low penetration power will produce a more even colour. |

| Painting | Average to good paint holding ability | |

| Lacquering | Good | Performed well in the tape test (i.e. small flakes of the coating were detached at intersections of cuts) and in the pull-off test (i.e. average strength of 29 kg/cm2). |

| Waxing | Good | Best results are obtained when using light-coloured waxes (e.g. Mellow Pine). |

| Drying | ||

| Ease of Drying | Easy to moderately easy | Few defects expected except in the most extreme cases. |

| Durability | ||

| Natural Decay Resistance | Slightly durable | Not appropriate for prolonged outdoor exposure. |

| Treatability | Impermeable | Can be improved by incising |